Supplemental Oxygen Therapy

Published (updated: ).

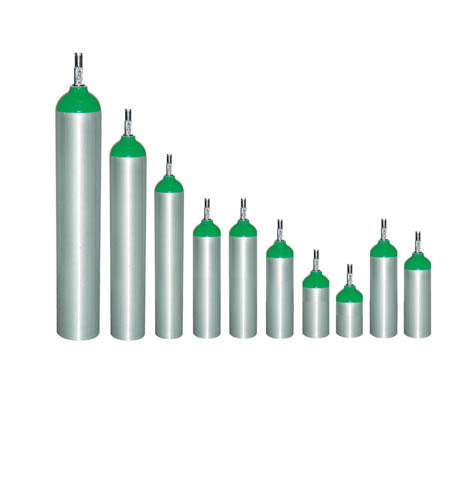

Portable Oxygen Cylinders

Ambulances typically carry D and E cylinders. These cylinder are portable and allow the ambulance crew to bring oxygen to the patient prior to transport. D cylinders carry 350 liters of oxygen and E cylinders carry 625 liters of oxygen.

Anything that flows can be measured with a unit of volume (just like 2 liters of Coke is liquid, but it flows). The oxygen is pumped into the steel cylinder under pressure. The regulator measures pressure inside the tank (not volume) which is typically full at 2000 psi. The oxygen is delivered in liters per minute. The confusion caused by monitoring the tank in psi and administering oxygen in liters per minute is a recipe for never knowing how much oxygen is in the tank. Typically, oxygen tanks are changed out at 500 psi, however the safe residual pressure for most tanks is 200 psi.

The regulator converts the higher pressure inside the cylinder to a lower pressure and gradually releases the gas in liters per minute. Medical oxygen regulators have 2 pins that fit into 2 pins on the oxygen tank (this system was devised to make it impossible to administer oxygen used in industrial applications as a medical gas).

Oxygen tanks have a post that comes out of the tank to allow the application of the regulator. The weakest link of the tank is considered to be the stem. For this reason, oxygen tanks are handled with care and often carried around in bags and boxes that protect the tank and regulator from damage while in operation. It is considered poor practice to stand an oxygen tank on it’s base, as it could tip over causing the stem to come out of the tank and become missile.

Liquid Oxygen

Oxygen is crucial for the treatment of patients with severe shortness of breath or difficulty of breathing. One of the ways in which this oxygen can be supplied is through Liquid Medical Oxygen (LMO). LMO is nothing but high purity oxygen used for medical treatment, and is developed for use in the human body.

Why in liquid state

Due to its low melting and boiling points, oxygen is in a gaseous state at room temperature. Liquification enables storage in larger volume and easier transportation. To remove the oxygen from the air, providers use a method called Fractional Distillation Method to produce pure oxygen from atmospheric air, which consists mostly of nitrogen and oxygen – 78% nitrogen, 21% oxygen and remaining 1% other gases including argon, carbon dioxide, neon, helium, and hydrogen.

In this method, gases from the air are separated into various components after cooling them into a liquid state and then liquid oxygen is extracted from it. Atmospheric air is first cooled to -181°C. Oxygen liquifies at this point. Since, the boiling point of Nitrogen is -196°C, it remains in a gaseous state. We then get the output as final purified liquid oxygen, which is then transported using cryogenic containers.

What are cryogenic containers?

Cryogenics is the production and behavior of materials at very low temperatures. A cryogenic liquid is defined as a liquid with a normal boiling point below –90°C.

Cryogenic liquid containers are specially designed for safe and economic transportation and storage of liquefied gases at cryogenic temperatures, lower than –90°C. These containers are highly insulated, in which liquid gases are stored at very low temperatures.

Safety precautions

If the temperature is high enough, many substances will burn in oxygen. Hence, it is equally essential to ensure proper fire safety measures and train all staff in the safe handling of oxygen. There are also additional requirements and rules for medical oxygen, including requiring a person to have a prescription to order medical oxygen.